Foundry-Enabled Patterning of Diamond Quantum Microchiplets for Scalable Quantum Photonics

By Jawaher Almutlaq 1,2,3, Alessandro Buzzi 1, Anders Khaykin 4, Linsen Li 1, William Yzaguirre 4, Maxim Sirotin 1, Gerald Gilbert 5, Genevieve Clark 4, Dirk Englund 1,3

1 Research Laboratory of Electronics, Massachusetts Institute of Technology, 50 Vassar St, Cambridge, 02139, MA, USA.

2 Materials Science and Engineering and Applied Physics, King Abdullah University of Science and Technology (KAUST), Thuwal, 23955, Saudi Arabia.

3 PhotonFoundries, Inc., Brookline, 02446, MA, USA.

4 The MITRE Corporation, Bedford, 01730, MA, USA.

5 The MITRE Corporation, Princeton, 08540, NJ, USA.

Abstract

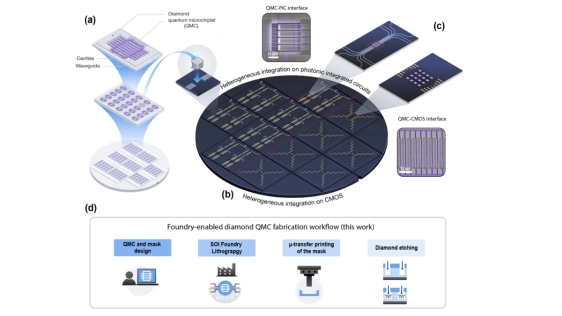

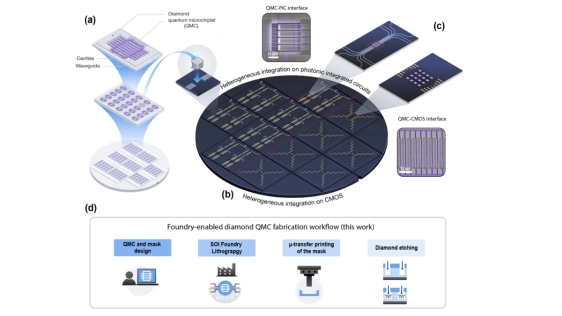

Quantum technologies promise secure communication networks and powerful new forms of information processing, but building these systems at scale remains a major challenge. Diamond is an especially attractive material for quantum devices because it can host atomic-scale defects that emit single photons and store quantum information with exceptional stability. However, fabricating the optical structures needed to control light in diamond typically relies on slow, bespoke processes that are difficult to scale. In this work, we introduce a manufacturing approach that brings diamond quantum photonics closer to industrial production. Instead of sequentially defining each device by lithography written directly on diamond, we fabricate high-precision silicon masks using commercial semiconductor foundries and transfer them onto diamond via microtransfer printing. These masks define large arrays of nanoscale optical structures, shifting the most demanding pattern-definition steps away from the diamond substrate, improving uniformity, yield, and throughput. Using this method, we demonstrate hundreds of diamond "quantum microchiplets" with improved optical performance and controlled interaction with quantum emitters. The chiplet format allows defective devices to be replaced and enables integration with existing photonic and electronic circuits. Our results show that high-quality diamond quantum devices can be produced using scalable, foundry-compatible techniques. This approach provides a practical pathway toward large-scale quantum photonic systems and hybrid quantum-classical technologies built on established semiconductor manufacturing infrastructure.

Quantum technologies promise secure communication networks and powerful new forms of information processing, but building these systems at scale remains a major challenge. Diamond is an especially attractive material for quantum devices because it can host atomic-scale defects that emit single photons and store quantum information with exceptional stability. However, fabricating the optical structures needed to control light in diamond typically relies on slow, bespoke processes that are difficult to scale. In this work, we introduce a manufacturing approach that brings diamond quantum photonics closer to industrial production. Instead of sequentially defining each device by lithography written directly on diamond, we fabricate high-precision silicon masks using commercial semiconductor foundries and transfer them onto diamond via microtransfer printing. These masks define large arrays of nanoscale optical structures, shifting the most demanding pattern-definition steps away from the diamond substrate, improving uniformity, yield, and throughput. Using this method, we demonstrate hundreds of diamond "quantum microchiplets" with improved optical performance and controlled interaction with quantum emitters. The chiplet format allows defective devices to be replaced and enables integration with existing photonic and electronic circuits. Our results show that high-quality diamond quantum devices can be produced using scalable, foundry-compatible techniques. This approach provides a practical pathway toward large-scale quantum photonic systems and hybrid quantum-classical technologies built on established semiconductor manufacturing infrastructure.

Keywords: Diamond quantum photonics, Foundry-compatible fabrication, Quantum microchiplets, Heterogeneous integration

To read the full article, click here

Related Chiplet

- DPIQ Tx PICs

- IMDD Tx PICs

- Near-Packaged Optics (NPO) Chiplet Solution

- High Performance Droplet

- Interconnect Chiplet

Related Technical Papers

- Codesign of quantum error-correcting codes and modular chiplets in the presence of defects

- ChipAI: A scalable chiplet-based accelerator for efficient DNN inference using silicon photonics

- Modular Compilation for Quantum Chiplet Architectures

- Low-Loss Integration of High-Density Polymer Waveguides with Silicon Photonics for Co-Packaged Optics

Latest Technical Papers

- Spatiotemporal thermal characterization for 3D stacked chiplet systems based on transient thermal simulation

- Interconnect-Aware Logic Resynthesis for Multi-Die FPGAs

- Scope: A Scalable Merged Pipeline Framework for Multi-Chip-Module NN Accelerators

- Scaling Routers with In-Package Optics and High-Bandwidth Memories

- TDPNavigator-Placer: Thermal- and Wirelength-Aware Chiplet Placement in 2.5D Systems Through Multi-Agent Reinforcement Learning