OKI Achieves 3D Integration of Thin-Film Analog ICs Using CFB Technology in Collaboration with Nisshinbo Micro Devices

Development of thin-film chiplet technology enabling heterogeneous integration

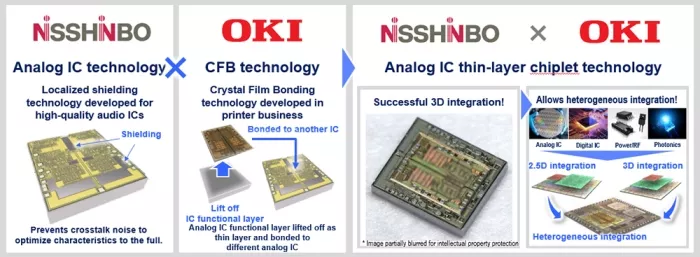

TOKYO, January 29, 2025 -- OKI (TOKYO: 6703), in collaboration with Nisshinbo Micro Devices Inc. (Head office: Tokyo; President: Keiichi Yoshioka), has successfully achieved three-dimensional (3D) integration (*1) of thin-film analog ICs (*2) using Crystal Film Bonding (CFB) technology (*3). This technology is applicable to heterogeneous integration (*4), which enables the integration of various types of semiconductor devices, such as analog ICs. The two companies plan to push ahead with product development based on this technology, targeting mass production by 2026.

With growing demand for enhanced functionality of semiconductor devices driven by the spread of AI and autonomous driving in recent years, attention has focused on chiplet technology (*5). Rather than integrating all functions into a single chip, chiplet technology divides functions into smaller chips, which are then integrated using 2.5D and 3D assembly techniques to achieve large-scale functionality integration at lower cost and with reduced space requirements. This division also improves yield and allows the optimal semiconductor manufacturing processes to be selected for each function, avoiding cost increases.

Applying the conventional chiplet technology to the 3D integration of low-end analog ICs entailed the following two challenges:

The first was to develop a 3D integration technology compatible with legacy processes (*6). 3D integration involves stacking chips vertically, which significantly improves integration density and miniaturization. However, electrical bonding between stacked chips typically requires Through Silicon Via (TSV) technology (*7), which entails significant investment into equipment and advanced process development. Implementing the process using conventional technologies thus previously incurred prohibitively high costs.

The second was to prevent the noise (crosstalk noise) generated by electrical signal interference. Analog ICs process continuous signal variations rather than the simple 0s and 1s of digital signals in digital ICs, and handle higher voltage signals compared to digital ICs, making them more susceptible to crosstalk noise. Stacking ICs also increases the proximity between circuit layers, increasing crosstalk noise.

To address the first challenge, OKI developed a new thin-film chiplet technology, consisting of lifting off and bonding (CFB process) followed by rewiring. It completely protects the analog IC's functionality and lifts off only the functional layer from the substrate. The thin-film analog IC is then bonded to another analog IC, enabling the successful 3D integration of thin-film analog ICs. Unlike 3D integration based on conventional TSV technology, which results in IC chip thicknesses in the range of tens to hundreds of micrometers, this technology produces thin-film analog ICs with thicknesses on the order of only several micrometers, allowing rewiring using conventional semiconductor lithography (*8). This rewriting enables the use of low-cost legacy processes, which are widely available.

To resolve the second challenge, proprietary localized shielding technology developed by Nisshinbo Micro Devices was applied to analog ICs. This technology shields only specific areas between upper and lower chips affected by interference, not the entire chip, suppressing signal interference without degrading circuit functionality. The technology draws on low-noise analog IC technology accumulated over the years by Nisshinbo Micro Devices for high-quality audio ICs, and has been proven to operate normally with crosstalk noise suppressed even under a high voltage output of 20 Vpp.

Overview of new technology

The successful 3D integration of thin-film analog ICs in the collaboration between Nisshinbo Micro Devices and OKI makes it possible to offer analog solutions by combining a wide range of different analog ICs. "Applying OKI's thin-film chiplet technology to the heterogeneous integration of all kinds of digital, analog, optical, power, and sensor semiconductor devices will also contribute to the development of new semiconductor devices," commented Kei Kato, an Executive Officer and Head of Global Marketing Center at OKI.

Looking ahead, OKI and Nisshinbo Micro Devices plan to develop new value-added products based on this technology, targeting mass production by 2026. Both companies will also explore partnerships and licensing opportunities.

Terminology

-

*1 :3D integration

A technology that stacks semiconductor devices vertically and connects the layers electrically.

- *2 :Analog ICs

Integrated circuits that process continuously varying analog signals for amplification, filtering, and other purposes in devices such as sensors.

- *3 :CFB (Crystal Film Bonding) technology

OKI's proprietary technology that lifts off the functional layer of a semiconductor device as a thin film and bonds it to a different material substrate using intermolecular forces. This direct bonding, which does without adhesives, allows for electrical, optical, and thermal propagation across the bond, enabling post-bonding semiconductor processes and the creation of new devices combining different materials and functionalities.

- *4 :Heterogeneous integration

A technology that combines different semiconductor devices with different process nodes (e.g., miniaturization technologies), functions (e.g., digital ICs, analog ICs), and materials (e.g., optical devices, next-generation semiconductors) into a single system.

- *5 :Chiplet technology

A technology that divides a single-chip semiconductor device into multiple smaller chips (chiplets) and integrates them using assembly technology. This enhances functionality while improving large-scale production yield.

- *6 :Legacy processes

Semiconductor manufacturing processes based on older technologies and equipment. These are still widely used in semiconductor processes due to their consistency, excellent reliability, and cost efficiency.

- *7 :Through Silicon Via (TSV) technology

A technique for forming vertical through-electrodes in silicon substrates to provide electrical connections between stacked semiconductor chips.

- *8 :Semiconductor lithography

A semiconductor manufacturing process technology that uses light or electron beams to form ultra-fine circuit patterns on semiconductor substrates.

Related link

About Oki Electric Industry Co., Ltd. (OKI)

Founded in 1881, OKI is Japan's leading information and telecommunication manufacturer. Headquartered in Tokyo, Japan, OKI provides top-quality products, technologies, and solutions to customers through its Public Solutions, Enterprise Solutions, Component Products, and Electronics Manufacturing Services businesses. Its various business divisions function synergistically to bring to market exciting new products and technologies that meet a wide range of customer needs in various sectors. Visit OKI's global website at https://www.oki.com/global/.

Related Chiplet

- Interconnect Chiplet

- 12nm EURYTION RFK1 - UCIe SP based Ka-Ku Band Chiplet Transceiver

- Bridglets

- Automotive AI Accelerator

- Direct Chiplet Interface

Related News

- OKI Develops Tiling crystal film bonding (CFB) Technology for Heterogeneous Integration of Optical Semiconductors onto 300 mm Silicon Wafers

- 2024 IEEE Electronic Components and Technology Conference to Spotlight Cutting-Edge Microelectronics Packaging Technologies; Photonic Devices, Heterogeneous Integration are Among Key Topics

- TSMC Announces Breakthrough Set to Redefine the Future of 3D IC

- UMC Launches W2W 3D IC Project with Partners, Targeting Growth in Edge AI

Latest News

- Where co-packaged optics (CPO) technology stands in 2026

- Qualcomm Completes Acquisition of Alphawave Semi

- Cadence Tapes Out UCIe IP Solution at 64G Speeds on TSMC N3P Technology

- Avnet ASIC and Bar-Ilan University Launch Innovation Center for Next Generation Chiplets

- SEMIFIVE Strengthens AI ASIC Market Position Through IPO “Targeting Global Markets with Advanced-nodes, Large-Die Designs, and 3D-IC Technologies”