Probing the Nanoscale Onset of Plasticity in Electroplated Copper for Hybrid Bonding Structures via Multimodal Atomic Force Microscopy

By Nicolas A. Alderete 1,2, Paresh D. Daharwal 3, Cristian V. Ciobanu 4, and Gheorghe Stan 1

1 Material Measurement Laboratory, National Institute of Standards and Technology, Gaithersburg, Maryland 20899, United States

2 School of Science and Engineering, The George Washington University, Washington, D.C. 20052, United States

3 Advanced Packaging Technology and Manufacturing, Intel Corporation, Hillsboro, Oregon 97124, United States

4 Department of Mechanical Engineering and Materials Science Program, Colorado School of Mines, Golden, Colorado 80401, United States

Abstract

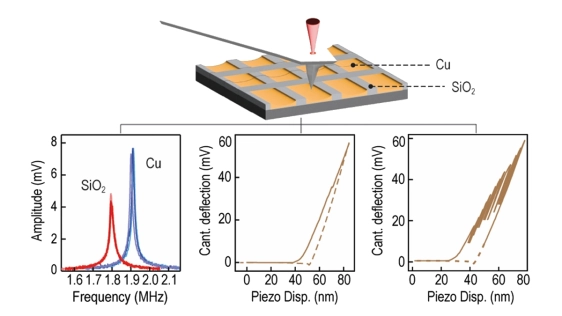

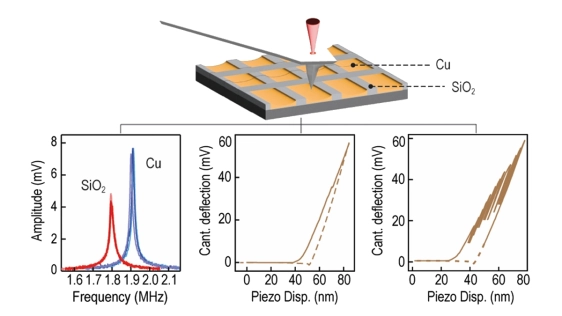

The slowdown of Moore’s law has elicited a paradigm shift whereby shrinking of in-plane dimensions is being replaced by 3D-stacking advanced packaging approaches to satisfy the ever-increasing demands for power, performance, area, and cost. Driven by the widespread use of metallic interconnects with submicron pitches, robust metrology for probing mechanical behavior at the nanoscale emerges as a key area of interest in the semiconductor industry. Here, we develop an atomic force microscopy (AFM)-based protocol for characterizing the incipient stages of plasticity and illustrate it on hybrid bonding-ready (prior to bonding) copper pads. We combined AFM’s high-resolution imaging with contact resonance and indentation techniques (including single- and multistep indentation) to characterize the mechanical heterogeneity of the material, quantify the nanoscopic yield stress statistics, and derive indentation stress–strain curves. From these measurements, we have clarified the mechanisms of early plasticity and determined the elastoplastic constitutive response of polycrystalline copper, including parameters such as elastic modulus, yield stress, and strain-hardening slope. Besides providing metrology relevant to various length scales, our approach offers a pathway to utilize an industry-standard instrument for characterizing the thermomechanical properties that are essential for the development of semiconductor structures.

The slowdown of Moore’s law has elicited a paradigm shift whereby shrinking of in-plane dimensions is being replaced by 3D-stacking advanced packaging approaches to satisfy the ever-increasing demands for power, performance, area, and cost. Driven by the widespread use of metallic interconnects with submicron pitches, robust metrology for probing mechanical behavior at the nanoscale emerges as a key area of interest in the semiconductor industry. Here, we develop an atomic force microscopy (AFM)-based protocol for characterizing the incipient stages of plasticity and illustrate it on hybrid bonding-ready (prior to bonding) copper pads. We combined AFM’s high-resolution imaging with contact resonance and indentation techniques (including single- and multistep indentation) to characterize the mechanical heterogeneity of the material, quantify the nanoscopic yield stress statistics, and derive indentation stress–strain curves. From these measurements, we have clarified the mechanisms of early plasticity and determined the elastoplastic constitutive response of polycrystalline copper, including parameters such as elastic modulus, yield stress, and strain-hardening slope. Besides providing metrology relevant to various length scales, our approach offers a pathway to utilize an industry-standard instrument for characterizing the thermomechanical properties that are essential for the development of semiconductor structures.

To read the full article, click here

Related Chiplet

- Interconnect Chiplet

- 12nm EURYTION RFK1 - UCIe SP based Ka-Ku Band Chiplet Transceiver

- Bridglets

- Automotive AI Accelerator

- Direct Chiplet Interface

Related Technical Papers

- Revamping the Semiconductor Industry with Hybrid Bonding

- Thermal Issues Related to Hybrid Bonding of 3D-Stacked High Bandwidth Memory: A Comprehensive Review

- Hybrid Bonding With Polymeric Interlayer Dielectric Layers Patterned by Nanoimprint Lithography

- Temporary Direct Bonding by Low Temperature Deposited SiO2 for Chiplet Applications

Latest Technical Papers

- Probing the Nanoscale Onset of Plasticity in Electroplated Copper for Hybrid Bonding Structures via Multimodal Atomic Force Microscopy

- Recent Progress in Structural Integrity Evaluation of Microelectronic Packaging Using Scanning Acoustic Microscopy (SAM): A Review

- LaMoSys3.5D: Enabling 3.5D-IC-Based Large Language Model Inference Serving Systems via Hardware/Software Co-Design

- 3D-ICE 4.0: Accurate and efficient thermal modeling for 2.5D/3D heterogeneous chiplet systems

- Compass: Mapping Space Exploration for Multi-Chiplet Accelerators Targeting LLM Inference Serving Workloads