Chiplet Integration in the Automotive Realm

As technology continues to advance, the automotive industry is rapidly transforming. The integration of chiplets, or small microchips that work together to form a larger, more powerful system, is at the forefront of these advancements.

This blog post is an excerpt from a presentation at CadenceLIVE 2024 in Silicon Valley by Pratibha Sukhija, Anunay Bajaj, and Ericles Sousa. We will examine the intricate details of chiplet technology in the automotive industry, exploring its significance, use cases, challenges, and verification processes.

The Role of Chiplets in Automotive Systems

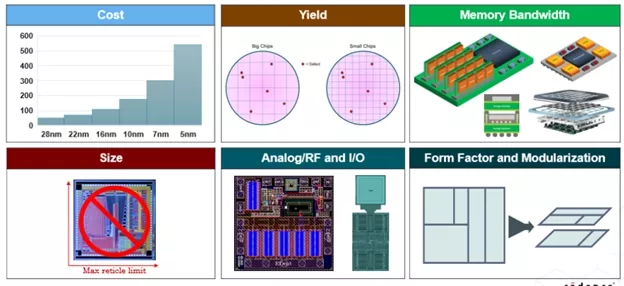

As we push the boundaries of what is achievable in automotive electronics, the limitations of monolithic designs have become apparent. Traditional single-die approaches are constrained by cost, yield, and manufacturing challenges. Enter chiplets and multi-die packaging—a solution that allows for greater scalability and functionality within a single package.

Why Chiplets?

- Reduced Waste: Integrating multiple smaller chips into a single package reduces material wastage.

- Improved Cost Efficiencies: The scalability of chiplets enables cost-effective production.

- Enhanced Yield: Smaller dies are easier to manufacture with higher yields.

- Scalability: Combining several smaller dies within a single package effectively mitigates the constraints associated with basic silicon monolithic scaling.

Chiplets enable a modular system design by integrating multiple smaller chips, each dedicated to different functionalities. This modularity is where UCIe (Universal Chiplet Interconnect Express) plays a pivotal role. UCIe provides a die-to-die serial interconnect that supports major protocols like CXL, PCIe, and streaming raw modem. It currently supports 2D and 2.5D packaging, with future developments aiming for 3D packaging.

To read the full article, click here

Related Chiplet

- Interconnect Chiplet

- 12nm EURYTION RFK1 - UCIe SP based Ka-Ku Band Chiplet Transceiver

- Bridglets

- Automotive AI Accelerator

- Direct Chiplet Interface

Related Blogs

- The Chiplet Center of Excellence sets new standards for the automotive industry

- The Chiplet Calculus: Navigating the Integration Crisis at the Hardware.AD Frontier

- 4 takeaways from the 2nd automotive chiplet conference

- Jumpstarting the Automotive Chiplet Ecosystem

Latest Blogs

- 3D-IC Test and Reliability: KGD Strategies, Access Architecture, & Failure Mode

- 3D-IC in AI, HPC, and 5G: Bandwidth, Latency, and Energy per Bit Advantages

- Bosch and the chiplet revolution: Enabling software-defined mobility

- Addressing the Biggest Bottleneck in the AI Semiconductor Ecosystem

- Thermal Management in 3D-IC: Modeling Hotspots, Materials, & Cooling Strategies