Automotive chiplets: The path towards modularity, improved cost structures and supply resilience

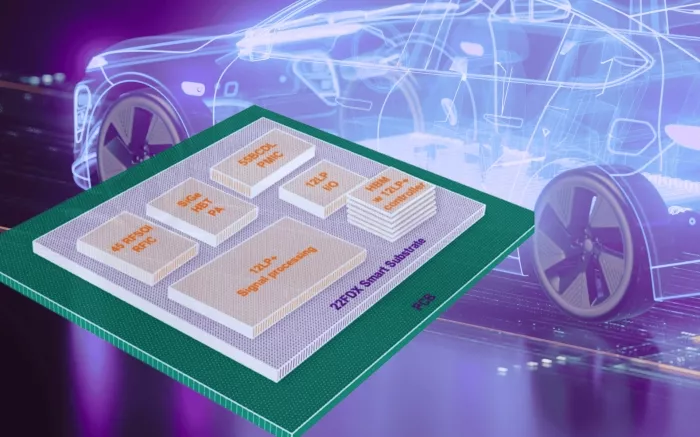

Chiplets are individual semiconductor dies, each responsible for a distinct system’s function. These dies are integrated using advanced packaging to create a complete, high-performance system. This heterogeneous integration of different process technologies includes FinFet for logic, FD-SOI for RF, BCD for power management and FD-SOI or CMOS for analog mixed signal to form a System-in-Package.

Unlike consumer or datacenter markets, the automotive product life cycles can last more than 15 years. Additionally, automotive systems rely on numerous analog sensors, switches, loads and actuators, requiring a range of analog and mixed signal IPs to support precise, safety-critical sensing and control.

These long product lifecycles, combined with the need to balance evolving analog and mixed-signal capabilities with increasing digital compute demands, are key drivers behind the adoption of chiplet-based systems in automotive. Automotive chiplets can ensure the integration of I/O chiplets and power management chiplets on mature process nodes to match the industry life cycles and unique product features. Meanwhile, other digital-heavy chiplets could be refreshed, requalified or sourced from multiple vendors.

Software-defined vehicles present significant opportunities for automotive chiplets across various domains, including cross-domain zonal controllers, central computer clusters, infotainment systems and smart sensor modules such as radars, lidars and sensor fusion systems. This can be accomplished by using various process technologies to address specific applications, including:

Compute & Processing

- Leading-edge CPU, GPU, and AI accelerator chiplets on sub-10nm nodes

- Low-power ASIL-D MCU/MPU chiplets with TSN Ethernet, 10BaseT1S, and CAN-XL on GF’s 12LP+ and 22FDX platforms

Memory & Data Handling

- Centralized non-volatile memory and HBM chiplets

Connectivity & I/O

- Swappable I/O chiplets for diverse applications, optimized on GF’s 22FDX

- Wireless chiplets (Wi-Fi, Bluetooth, UWB) on GF’s 22FDX

Sensing & Perception

- Radar RF front-end chiplets on GF’s 22FDX

- Lidar front-end chiplets on GF’s silicon photonics platform

- Sensor fusion modules

Power Management

- Power management and distribution chiplets on GF’s 55BCD platform

Enabled by technology optimization, automotive chiplet systems improve system-level cost efficiency by scaling wafer costs across leading-edge and mature process nodes, and by enhancing overall system yields compared to large monolithic SoCs. Chiplet architectures also offer scalability and modularity by mixing and matching different chiplets to support various performance requirements. Additionally, they offer supply chain flexibility through multi-vendor sourcing of leading-edge chiplets, helping address varying customer and regional needs

However, automotive chiplet development faces several challenges. These include significant packaging investments due to complexity and strict reliability standards; limited cooling capabilities compared to datacenters impacting thermal management of high-power chiplets and long-term thermal stress that can accelerate package degradation. Chiplet systems also require robust ecosystem frameworks for integration and interoperability. While industry-standard EDA tools are beginning to support chiplet simulation, design, and verification flows; these are not as established as those for monolithic solutions. Current die-to-die standardization is primarily driven by the UCIe Consortium, with ongoing efforts to establish standards for manufacturing and testability.

Earlier in 2025, GlobalFoundries (GF) announced its first-of-its-kind advanced packaging and test capabilities center in New York, focused on essential chips for AI, automotive, and other applications. The facility will feature new production capabilities for advanced packaging, wafer-to-wafer bonding, assembly and testing of 3D and heterogeneous integrated chips using GF’s 12LP+, 22FDX, and other leading platforms.

In addition to these planned investments and advancements, GF is expanding its IP portfolio to support chiplet-based systems and is actively collaborating with industry leaders on standardization, reliability and qualification to meet the rigorous demands of automotive applications.

Related Chiplet

- Interconnect Chiplet

- 12nm EURYTION RFK1 - UCIe SP based Ka-Ku Band Chiplet Transceiver

- Bridglets

- Automotive AI Accelerator

- Direct Chiplet Interface

Related Blogs

- The Automotive Industry's Next Leap: Why Chiplets Are the Fuel for Innovation

- The Need for Chiplets, and UCIe in Automotive

- Driving the Development and Deployment of Chiplets in the Automotive Industry

- Accelerating Automotive SoC Design with Chiplets

Latest Blogs

- Advancing Europe’s Automotive Chiplet Vision: Arteris Joins CHASSIS to Accelerate Software-Defined Mobility

- 3D-IC Market Outlook: Technology Roadmaps, Readiness, and Design Implications

- Cadence 3D-IC Success Stories: Faster Bandwidth, Lower Power, On-Time Tapeouts

- 3D-IC Test and Reliability: KGD Strategies, Access Architecture, & Failure Mode

- 3D-IC in AI, HPC, and 5G: Bandwidth, Latency, and Energy per Bit Advantages